NVIDIA Blackwell Revolutionizes Computer-Aided Engineering with Real-Time Digital Twins and 50x Performance Boost

NVIDIA has unveiled its groundbreaking Blackwell architecture, set to revolutionize computer-aided engineering (CAE) by delivering an unprecedented boost in performance for real-time digital twins and complex simulations. By integrating cutting-edge GPU technology with advanced AI acceleration, Blackwell promises to transform industries reliant on high-fidelity simulations, including aerospace, automotive, and industrial manufacturing.

Unleashing Unparalleled Performance for CAE

Traditional engineering simulations have long been constrained by computing power limitations, often requiring hours or even days to complete complex analyses. The introduction of NVIDIA Blackwell changes the game by offering up to 50x performance improvements over previous-generation solutions. This leap in computational efficiency allows engineers to execute real-time simulations, significantly reducing development cycles and accelerating innovation.

Blackwell achieves this remarkable speed through a combination of enhanced GPU cores, optimized memory bandwidth, and AI-driven acceleration. These advancements enable real-time digital twins, providing an interactive and highly accurate representation of physical systems. Engineers can now test and refine designs in virtual environments before deploying them in the real world, cutting costs and improving reliability.

Real-Time Digital Twins: A Game-Changer for Engineering

Digital twins are virtual models that mirror real-world objects, processes, or systems, continuously updating with live data. With Blackwell, these digital twins can now function in real time, enabling engineers to monitor performance, predict failures, and optimize efficiency dynamically. This capability is particularly valuable in industries where precision and reliability are paramount, such as aerospace and automotive manufacturing.

By leveraging AI and high-speed computing, Blackwell enables real-time adjustments and iterative testing without the need for physical prototypes. This dramatically shortens product development cycles, minimizes errors, and enhances overall design accuracy. Companies can now conduct predictive maintenance, streamline workflows, and achieve higher operational efficiency with unprecedented ease.

Enhanced AI and Machine Learning Integration

AI has become an essential component of modern engineering simulations, and Blackwell takes this integration to the next level. With dedicated AI acceleration cores, Blackwell enhances machine learning models used in CAE applications, providing faster insights and improving predictive accuracy. Engineers can now leverage AI-driven optimizations to refine designs, simulate real-world conditions more effectively, and automate complex calculations.

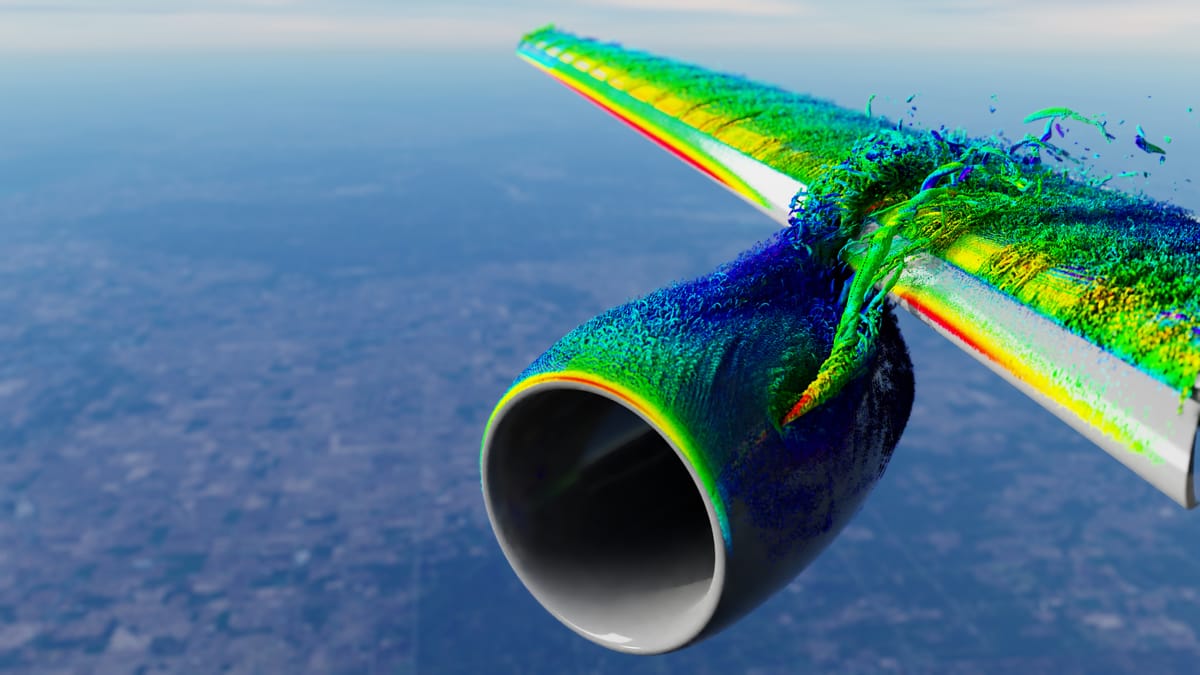

These AI-powered enhancements also extend to computational fluid dynamics (CFD), finite element analysis (FEA), and structural simulations. With Blackwell, engineers can perform these high-complexity tasks with unprecedented speed and precision, unlocking new possibilities for innovation across multiple sectors.

Transforming Key Industries with Advanced Simulation Capabilities

Automotive Industry

The automotive sector relies heavily on simulation for vehicle design, crash testing, and aerodynamics optimization. Blackwell’s real-time capabilities allow engineers to run crash simulations and aerodynamic analyses in a fraction of the time, leading to safer, more efficient vehicle designs. Autonomous vehicle development also benefits, as Blackwell enables rapid AI model training and testing for real-world scenarios.

Aerospace and Defense

In aerospace, precision and reliability are critical. Blackwell enhances the simulation of aircraft components, aerodynamics, and propulsion systems, reducing the time required for certification and improving overall safety. Defense applications also gain from real-time digital twin capabilities, allowing for predictive maintenance and mission-critical decision-making.

Industrial Manufacturing

Manufacturers can now optimize production processes through AI-driven simulations powered by Blackwell. Digital twins provide real-time insights into machinery performance, enabling predictive maintenance and minimizing downtime. This leads to cost savings, increased efficiency, and improved product quality.

Scalability and Cloud Integration

One of Blackwell’s standout features is its seamless scalability, allowing enterprises to deploy simulations across local workstations, cloud-based infrastructures, and data centers. Companies can leverage Blackwell-powered cloud solutions to perform large-scale simulations without investing in on-premise hardware, making high-performance computing more accessible than ever.

Additionally, Blackwell integrates with leading engineering software platforms, ensuring compatibility with existing workflows and tools. This makes adoption seamless, allowing companies to harness Blackwell’s power without disrupting their established processes.

Future Prospects and Industry Impact

The introduction of Blackwell marks a significant milestone in the evolution of computer-aided engineering. As more industries adopt this cutting-edge technology, the boundaries of what’s possible in simulation and digital twin applications will continue to expand. With real-time insights, enhanced AI capabilities, and unprecedented performance gains, Blackwell is set to redefine how engineers and researchers approach complex problem-solving.

By providing a scalable, efficient, and intelligent solution, Blackwell paves the way for the next generation of innovation in engineering and beyond. Its impact will be felt across industries, from designing safer vehicles to optimizing industrial processes and advancing aerospace technology. As companies embrace the power of real-time simulations, the future of engineering looks faster, smarter, and more efficient than ever before.